Choosing the right modular connectors can seem hard. There are many choices to pick from. You need one that works well for signal integrity. It should also resist vibration and last a long time. Many industries, like automotive and manufacturing, want connectors that are easy to fix.

They also need to work in tough places. As technology gets better, companies like Pulse Electronics Network make new connectors. These connectors help new systems and support green practices. You might need flexibility or want to plan for the future. Sometimes you need something special, like an lr44 battery equivalent. Your choice should match what you need.

Application Needs

Use Case

When you pick a modular connector, think about where you will use it. Modular connectors are important in many areas. You can find them in:

-

Industrial automation

-

Rail systems

-

Telecom and datacom

-

Consumer electronics

Each field needs something different. In factories, modular connectors help machines talk to each other. They let you fix or upgrade parts without stopping everything. In rail systems, these connectors work well with lots of shaking and dust. For telecom and datacom, modular connectors link phones, computers, and network devices. They make wiring easy and let you change parts quickly. In consumer electronics, modular connectors help keep devices small and simple.

Tip: Always pick a connector that fits your environment. A connector for an office may not work in a train or factory.

Requirements

After you know how you will use the connector, look at what it must do. High-performance places need connectors that last and handle stress. Here are some important things to check:

-

Vibration resistance: The connector should stay tight even if things shake.

-

Miniaturization: Smaller connectors save space and add more features.

-

High contact density: More pins mean more signals in one connector.

-

EMI shielding: Shielded connectors keep signals safe from noise.

-

Environmental sealing: Look for IP67 or IP68 ratings to block water and dust.

-

Corrosion resistance: Stainless steel or special plastics last longer.

-

High current handling: Some connectors can carry up to 200 amps.

-

Mechanical retention: Latches help keep connectors from coming loose.

-

High mating cycles: Some connectors can be plugged in and out over 5,000 times.

You should always check if the connector meets industry rules. This helps you avoid trouble later. Picking the right connector keeps your system safe, strong, and easy to fix.

Modular Connectors: Types

When you pick modular connectors, you will see many kinds. Each kind is made for a special job. Some are best for computers or phones. Others are good for cars or factories. The table below shows some common types and where they are used:

|

Connector Type |

Description / Typical Use |

Market Share Insight |

|---|---|---|

|

4P4C |

Handset connector used in telephone handset cords |

Largest share in telephone industry |

|

6P6C |

Modular connector with 6 positions and contacts |

Used in phones and some data devices |

|

8P8C (RJ45) |

Ethernet and network connections |

Widely used in networking |

|

10P10C (RJ50) |

Proprietary data transfer systems |

Used in special equipment |

Note: Telephone connectors are used the most. RJ45 connectors are also very popular for networks.

RJ45

You will see RJ45 connectors in most computer networks. They have eight spots for wires and eight contacts. This lets them carry four pairs of wires. You use RJ45 to link computers, switches, and routers. They have a plastic clip that locks them in place. This helps keep the connection safe.

RJ45 connectors use wiring rules called T568A and T568B. These rules make sure your cables work everywhere. You can get RJ45 connectors with or without shields. Shielded ones protect your data from outside noise. Some RJ45 connectors come in different shapes to fit your space.

Some RJ45 connectors have extra things:

-

Keying stops you from plugging them in wrong

-

Integrated magnetics help your signal stay strong

-

Waterproof designs let you use them outside

Tip: Not every 8P8C connector is a real RJ45. Real RJ45 connectors have special wiring and keying.

Terminal

Terminal modular connectors help you join wires in machines and panels. You will find them in factories, power plants, and big machines. These connectors make it easy to connect many wires. You can use them for sensors, relays, and power supplies.

Here are some ways to use terminal connectors:

-

Connect wires to ground for safety

-

Add fuses to stop too much current

-

Send power to many devices

-

Make panels safer and easier to fix

Terminal connectors come in many shapes. Some let you plug and unplug wires fast. Others have special angles for tight spaces. You can find terminal connectors for small or large amounts of electricity. They are strong and last in tough places.

Automotive

Automotive modular connectors help cars work safely and well. You will find them in electric, hybrid, and regular cars. These connectors carry power, data, and signals between car parts.

Automotive connectors have these features:

-

Fast data for cameras and entertainment

-

High power for batteries and motors

-

Strong locks to keep connections tight

-

Weatherproof to block water and dust

-

Flexible for different wire sizes and colors

Automotive connectors must follow strict rules for heat, shaking, and sealing. They help you fix or upgrade car systems easily. As cars get more tech, these connectors support new features like self-driving and safety.

Note: Top brands keep making better automotive connectors for new car needs.

Features

Performance

You want your connectors to work well and stay strong. The material inside the connector matters a lot. Full copper connectors let electricity move fast and with little loss. Gold-plated connectors have a thin gold layer on the contact points. This gold helps stop rust and keeps the connection good, even after many uses.

Here is a look at full copper and gold-plated connectors:

|

Aspect |

Full Copper Connectors |

Gold-Plated Connectors |

|---|---|---|

|

Corrosion Resistance |

Can rust and form layers that hurt the connection. |

Gold stops rust and keeps the connection strong. |

|

Electrical Conductivity |

Lets electricity move better than gold. |

Not as good as copper, but gold stays steady over time. |

|

Durability and Longevity |

Wears out faster and does not last as long. |

Gold lasts longer and works well in tough places. |

|

Environmental Stability |

Does not work well in wet or harsh places. |

Gold works well even with water, chemicals, or heat. |

|

Plating Thickness Impact |

N/A |

Thicker gold means better protection and longer life. |

|

Mechanical Properties |

N/A |

Hard gold helps connectors last through many uses. |

|

Cost Considerations |

Cheaper but needs more fixing and replacing. |

Costs more but lasts longer and needs less fixing. |

Gold-plated connectors are best for tough places. Studies show gold stops rust and keeps the contact area clean. This means your connection stays strong, even if you plug and unplug it a lot. Gold-plated connectors are used in airplanes and factories where you need them to work every time.

Bandwidth is also important for performance. RJ45 Cat6A and Cat5e connectors can go up to 1 Gbps per port. These connectors block outside noise, so your data moves fast and safe. If you need to send lots of data, pick connectors that match your speed.

Tip: Pick connectors with the right material and speed for your job. Gold-plated connectors cost more, but they last longer and work better in hard places.

Durability

You want your connectors to last a long time. The material and design decide how long they work. Copper and aluminum connectors can last 30 to 40 years in normal use. How long they last depends on stress, heat, and shaking.

Things like heat and wet air can make connectors wear out faster. Water and wetness cause rust, which hurts the metal inside. High humidity lets water get into the insulation, which can cause leaks. Even in a sealed box, temperature changes can make water build up and hurt the connectors.

The best connectors use strong materials and good seals. M12 and M-series connectors have tough covers and locks. These keep out dust, water, and shaking. Some connectors meet IP65 to IP69K ratings, so they block water and dust even in hard places.

|

Material |

Connector Type |

Average Lifespan (Years) |

Notes |

|---|---|---|---|

|

Copper |

Medium voltage connector |

30–40 |

How long it lasts depends on pressure and the place. |

|

Aluminum |

Medium voltage connector |

30–40 |

Like copper, but heat and dirt can make it wear out. |

Note: Always check the connector’s rating for heat and wetness. Most connectors work from -60°C to 200°C, but tough places can make them wear out faster.

Compatibility

You need connectors that fit your cables and devices. Modular connectors come in sizes like 4, 6, 8, or 10 positions. Small plugs can fit in bigger jacks, but this can break the jack. Always match the plug and jack size.

Connectors work with different wire types. Some are for solid wires, others for stranded wires. Using the wrong one can make a weak connection. Shielded connectors need shielded cables to block outside noise.

Many connectors follow rules like ANSI/TIA-568 and IEC 60603-7. These rules help your connectors work with many brands and devices. Some brands use special shapes or locks. These stop you from mixing up data and phone cables, but can limit what you use together.

Common problems with compatibility are:

-

Connectors that do not match and need adapters

-

Loose connections that can fail

-

Different ways to mount that make setup hard

-

Power or dimming problems if rules do not match

-

Sparks, heat, or wrong power from bad pinouts

You can avoid these problems by using connectors from the same brand or checking the list for what works together. Always test your setup before you finish putting it in.

Tip: Pick connectors that match your cable type, size, and rules. This helps you avoid damage and keeps your system safe.

Brands

Leading Brands

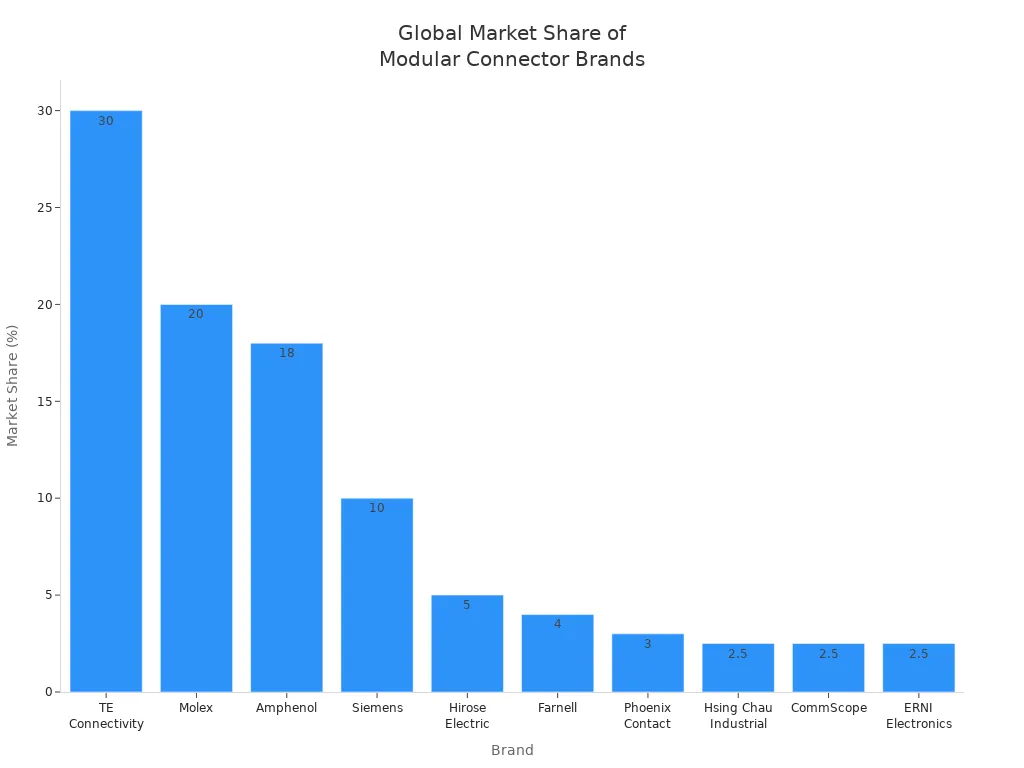

When you shop for modular connectors, you will see many brands. Some brands are very popular because their products are strong and customers like them. The table below lists the top brands, how much of the market they have, and what they do best:

|

Brand |

Approximate Global Market Share |

Key Strengths and Focus Areas |

|---|---|---|

|

TE Connectivity |

~30% |

Strong R&D, diverse portfolio, automotive, industrial, communication sectors |

|

Molex |

~20% |

Telecommunications focus, strategic partnerships, robust product line |

|

Amphenol |

~18% |

Military, aerospace, industrial markets, strategic acquisitions |

|

Siemens |

~10% |

Automation, digitalization, Industry 4.0, smart connectivity |

|

Hirose Electric |

~5% |

Precision connectors, miniaturization, consumer electronics |

|

Farnell |

~4% |

Distributor with broad product assortment and supply chain efficiencies |

|

Phoenix Contact |

~3% |

Industrial connectivity, automation, smart technology solutions |

|

Hsing Chau Industrial |

~2-3% |

Niche markets, partnerships |

|

CommScope |

~2-3% |

Niche markets, partnerships |

|

ERNI Electronics |

~2-3% |

Niche markets, partnerships |

You can also find brands like Yazaki, LEADSIGN, LEMO, and Weidmüller. Each brand has something special to offer.

Brand Comparison

Every brand is different and has its own price. For example:

-

Amphenol makes connectors for smart cars, ADAS, and cameras. Their OSFP connectors use special heat materials. They are easy to install because you do not need tools.

-

TE Connectivity works hard on research and making products that last. Their connectors move data fast and have keying to stop mistakes. Some TE RJ45 plugs use "black dot" or "white dot" dies for crimping. The right tool helps you make a safe connection.

-

Molex sells sealed, tough connectors for hard places. Their prices range from cheap to expensive, so there is something for everyone.

-

LEADSIGN gives good quality for a fair price. Many people think these connectors are a smart choice.

-

Weidmüller costs more at first but lasts longer and needs less fixing. People like how strong they are.

People who buy connectors say Samtec, WAGO, and Phoenix Contact are very reliable and last a long time. Amphenol, LEMO, Hirose Electric, and TE Connectivity also get good reviews for lasting quality.

When you pick a brand, check if you need special tools to put it in. For example, AMP RJ45 plugs need the right die so you do not break them. Reading reviews and checking ratings can help you choose a brand that fits your needs and budget.

Installation

Ease

You want to install connectors fast and without trouble. Modular connectors make this easier for you. Many have standard parts that fit together well. You can pick what you need without being an expert. Some brands sell connectors already put together. These save you time and help you make fewer mistakes. You can use online tools to plan your connector before you buy it.

You do not need to solder for upgrades or changes. This means you do not need special tools. Many connectors use colors and need little force to connect. These things help you not make mistakes. Plug-in designs let you change parts quickly. The simple design makes it easy to teach workers.

Tip: Pick connectors with guide pins or keying. These help you line up parts and stop pin damage.

But sometimes, you may still have problems:

-

Putting connectors together can take a while, especially if they have threads.

-

Pins can bend or break if you twist or do not line up parts.

-

Threaded connectors can get stuck or dirty.

-

Seals and clamps can get hard or crack from sun or weather.

-

You might need to order and put together many small pieces.

-

Small pins are hard to fix in the field.

-

If you are in a hurry, these problems can get worse.

Some companies sell connectors already put together to help you avoid these problems.

Maintenance

Taking care of connectors helps them last longer. You can do these things to help them work well:

-

Use connectors with seals and gaskets to keep out dust and water.

-

Pick materials that work in hot or cold places.

-

Choose connectors with shock-absorbing covers and locks.

-

Follow the maker’s guide to connect them right.

-

Clean and check connectors often. Look for rust, dirt, or loose parts.

-

Keep connectors safe from chemicals, oil, and bad weather. Cover them when not used.

-

Store extra connectors in dry, cool places. Keep them away from sun and heat.

Note: Good connectors with IP67 or IP68 ratings and materials that do not rust last longer and need less fixing.

If you take care of connectors and install them right, you will not have to fix them as much. Your system will keep working well.

Budget

Cost

When you pick modular connectors, you might check the price first. But the real cost is more than just the first price. You need to think about all the money you will spend over time. This is called the total cost of ownership. It means you look at every cost for your system’s life.

-

Modular connectors can cost more at first than hardwiring.

-

You save money because plug-and-play parts are fast to set up.

-

Preassembled connectors come ready, so you pay less for work.

-

You do not need as many skilled workers, which saves money.

-

Maintenance is easier and faster, so you have less downtime.

-

You need fewer spare parts, so you spend less on storage.

-

Modular connectors help you avoid mistakes from bad wiring.

Tip: A lower price at first does not always save money later. Think about what you will pay for repairs, downtime, and upgrades.

Value

You want your connectors to give you good value. Premium modular connectors do more than just work. They use better materials and last longer. You get extra features that help your system and save money over time.

|

Feature |

Budget Modular Connectors |

Premium Modular Connectors |

|---|---|---|

|

Materials |

Plastic, MDF, or particleboard |

Steel, solid hardwood, aircraft-grade aluminum |

|

Weight Capacity |

25-35 pounds per shelf |

50-75+ pounds per shelf |

|

Connection Mechanism |

Plastic parts that wear out |

Metal-to-metal, precision-made |

|

Stability & Durability |

Can wobble or fail |

High strength, no wobbling |

|

Warranty |

1-3 years |

10-25 years |

|

Extra Services |

Few or none |

Free design help, easy installation |

|

Longevity |

3-5 years |

Decades |

Premium connectors may cost more, but they last longer and need less fixing. You get better support, longer warranties, and stronger parts. Over time, you spend less on repairs and replacements. This helps your system keep working well.

Picking the right connector means looking at both cost and value. A smart choice now can save you money and problems later.

Selection

Shortlist

You can make a smart choice by creating a shortlist of connectors that fit your needs. Follow these steps to narrow down your options:

-

Define what you need. Write down the electrical needs like current, voltage, and resistance. Think about how many times you will connect and disconnect the parts. Check if you need the connector to work in hot, cold, or wet places.

-

Look at catalogs from trusted brands. Ask suppliers for advice if you are not sure.

-

Pick only the connectors that meet your main needs. Remove any that do not fit your list.

-

Study the connectors you picked. Ask for samples if you can. Test them in your real setup.

-

Think about the future. Will you need more features later? Make sure the connector can handle upgrades.

-

Choose the best one by looking at how well it works, how long it lasts, how much it costs, and how easy it is to get.

-

Test your final choice in your system. Make sure it works well and stays safe.

Tip: Always check for industry standards and safety rules before you decide.

Checklist

Use this checklist to compare Modular Connectors for your project. This table shows what to look for and why it matters:

|

Essential Item |

Description |

Why It Matters |

|---|---|---|

|

Voltage Rating |

Highest safe voltage |

Prevents short circuits and keeps you safe |

|

Current Rating |

Maximum current it can carry |

Stops overheating and power loss |

|

Operating Temperature |

Temperature range for use |

Keeps connector working in hot or cold places |

|

Contact Materials |

Metals used for contacts (gold, copper, tin, etc.) |

Affects how well it works and how long it lasts |

|

Environmental Protection |

IP rating for dust and water |

Needed for harsh or outdoor environments |

|

Mating Cycles |

How many times you can connect/disconnect |

Shows how durable it is |

|

Contact Resistance |

Resistance at the contact point |

Lower is better for signal and power |

|

Connector Size & Type |

Shape and size |

Must fit your space and design |

|

Mounting Style |

How you attach it (panel, cable, board) |

Must match your setup |

|

Polarization/Keying |

Features to prevent wrong connections |

Stops mistakes and damage |

|

Certifications |

UL, RoHS, IEC, ISO, REACH |

Shows it meets safety and quality standards |

Note: Always check the connector’s certifications to make sure it meets your industry’s rules.

Picking the right connector means you need to know where you will use it. You should find connectors that are strong, simple to put in, and easy to fix. Experts say you should look for things like screw-machined contacts, modular subcomponents, and clear color codes. Here is a quick checklist:

-

Make sure you know what your system needs.

-

Pick connectors that are easy to plug in and use.

-

Choose parts that follow world rules.

-

Find options that let you fix things fast.

-

Think about price, quality, and how fast you get it.

If you are not sure, ask a trusted supplier or expert for help. You can make a good choice if you follow these steps.

FAQ

What is a modular connector?

A modular connector is a plug or socket that lets you connect wires or cables. You can use it to join devices or parts. You can change or replace it easily.

How do I know which connector size I need?

You should check your device’s manual or label. Look for the number of pins or positions. You can also measure the connector or ask your supplier for help.

Why do some connectors have gold plating?

Gold plating helps stop rust and keeps the connection strong. You get better performance and longer life. Gold also works well in wet or harsh places.